China company: TaiYing Industrial Park, HongMei Town, DongGuan City, GuangDong Province, China Taiwan company: 18F.-2, No.77, Sec. 1, Xintai 5th Rd., Xizhi Dist., New Taipei City, Taiwan

Argentina

Egypt

Malaysia

Sri Lanka

Singapore

Indonesia

Vietnam

China

KaDar Computer CO., LTD. KDMTO-1224 Shipping Mark detection device (first inspection)

KaDar Computer CO., LTD. KDMTO-1224 Shipping Mark detection device (first inspection)

KaDar Intelligent palletizing manipulator Intelligent palletizing manipulator

KaDar Intelligent palletizing manipulator Intelligent palletizing manipulator

KaDar Intelligent palletizing manipulator Intelligent palletizing manipulator

KaDar Intelligent palletizing manipulator Intelligent palletizing manipulator

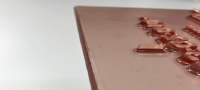

Anilox Roll Scoring

The anilox roll has been referred to as the heart of the printing press. It carries the huge responsibility of delivering the precise amount of ink required to create an image exactly according to the customer’s specifications. That’s a big job! If anilox rolls are taken care of, they are your workhorses: consistently and repeatedly executing the desired image, job after job. They can last for years and provide a great return on your investment.So the “health” of your anilox rolls is extremely important. There are several steps you can take to maintain their integrity. First, follow a good cleaning regimen to prevent ink from drying in cells. Plugged anilox cells can’t carry the volume of ink for which they were designed. Second, make sure to handle the rolls properly to avoid damaging the ceramic coating. Once the edges become chipped, ink and solvent can leach under the surface and ruin the roll.Protect your rolls from scoringA third way to get the most out of your anilox investment is to protect your rolls from scoring. Anilox scoring occurs when a piece of metal becomes trapped against the doctor blade as the roll rotates. The fragment causes a deep scratch, or “score line,” destroying the cells in a stripe around the circumference of the roll. Not only is this expensive in terms of repairing or replacing the roll, but also costs a lot in substrate and ink waste, press downtime and unhappy customers.If the roll’s surface becomes scored, the defects will show in the printed image. Sometimes a score line is a deep gouge across several cell widths. The band of damaged cells results in a dark streak in the print as more ink is delivered in this area. More often, the metal fragment wears down the walls of the cells, resulting in a “polishing” score line. In this case, the affected part of the anilox roll is not able to carry as much ink as the surrounding cells, and the corresponding area of print appears as a light streak.Causes of anilox scoringWhile there are many causes of anilox scoring, the most common ones relate to the use of steel doctor blades. Large pieces of the blade can break away as it wears or if the blade is installed with too much pressure. An excessive amount of pressure on the tip will cause it to bend back and eventually fracture off. Excessive pressure can occur when an operator neglects to adjust the blade holder setting when replacing a worn blade with a new (wider) one. Sometimes an operator will intentionally over-pressure the blade to compensate for other problems such as chamber leaks, chamber misalignment, mechanical creep or warped or rippled blades.Some ways to prevent anilox roll scoring are:· Ensure proper chamber alignment and blade installation· Use non-metallic doctor blades· Do not over-pressure blades· Clean anilox rolls regularly· Do not run the press dry or let ink dry in cells· Filter ink to remove metal fragmentsOnce a roll is scored, it must be reconditioned or replaced at the cost of hundreds to thousands of dollars. Not to mention lost substrate, ink waste, press downtime and being without the roll while it’s being reconditioned or replaced. Treat your anilox rolls like the important parts of the press that they are; in addition to proper cleaning and handling, preventing score lines will go a long way to ensure that you get the most out of your anilox investment!

1116 views0 0

Rotary Die Cutting vs Flatbed Die Cutting, how to Choose?

Now the world corrugated packaging industry uses the most two die-rotary die cutting and flatbed die cutting, many companies are confused, so how to make a choice? Now it’s time to take a closer look at the two die cutting methods available-rotary die cutting and flatbed die cutting. Which one is right for you? The box maker corrugated plant has both available in-house, and each method is used regularly in different situations.The Working Speed Between Rotary and FlatbedThe Rotary Die CuttingIt is usually one of the units of flexo printing machine, it’s called die-cut unit. Speed often depends on the type of carton produced and die cutting type. The normal production speed is 150-250 piece/min, some machine can reach 350 piece/min.Flatbed Die CuttingTo be exact, there are 3 typis in the market, one is manual, semi-automatic and full automatic. The speed of the device in type 3 is completely different. The manual speed around 30 piece/min, semi-automatic is around 60 piece/min. Full automatic die cutting max speed can reach 100-120 piece/min.Cutting DiesCutting dies are long lasting, quality structures and present a one-time charge for your company. The main tenance, storage, and cleaning of all dies is covered in the initial price you pay. Rotary steel dies are more expensive than flatbed dies because the wood for a rotary die is circular in shape, and the method for making these is more extensive. Yet, looking at the price of the steel die alone is not enough information to make an informed decision. There are many factors to consider when choosing the best method for your packaging needs. Our estimating team will take into account the following factors to determine the right direction for you and your organization: How many will you be ordering? Rotarysteel dies can be 30-100% more expensive than a flatbed die, but the rotary machinery can run more pieces at once due to a larger blank size and faster speed. So, while the initial steel die may cost more, a lower per-each price can offset the die cost quickly. Will you be buying multiple orders on a regular basis, oris it a one-time purchase? If you are purchasing a specific product for a one-time promotion or a single distribution, then a less expensive flatbed die may be the best way to go. But, if you have regular usage of a specific product and plan on purchasing multiple orders of a particular package, the rotary machine will offer a lower piece price and will quickly offset the higher die cost.

1265 views0 0

How Humidity Affects Corrugated Boxes

We’re all familiar with how easily paper can soak up liquids. Corrugated “cardboard” boxes are no exception. The porosity of wood fibers, which is what corrugated boxes are made of, allows it to absorb and release moisture, a phenomenon that is known as hygroscopy.We should do our best to keep boxes relatively dry because humidity can have a huge impact on their performance. And unfortunately, humidity is one factor that cannot always be controlled. While having a certain amount of moisture in the air (around 6% – 7%) will ensure proper creasing, avoid cracks, maintain good bending and impact resistance, as well as cushioning and shock absorption, higher humidity levels can actually have a negative impact on those characteristics of corrugated board that we value most. In this table below published in the Handbook of Package Engineering (c.1992), you can see that the greater the humidity the less stacking strength a box has. For example, at 50% relative humidity (RH) a corrugated box is at 80% of its potential stacking strength. In very humid environments, such as a warehouse with an uncontrolled climate in the summertime, stacking strength is greatly reduced. At 85% RH, a box has 50% of its potential stacking strength.In a more recent publication, The Fundamentals of Packaging Technology (c.2013), an increase in RH from 40% to 90% “can result in a loss of about 50% of a corrugated container’s stack strength.” Therefore a corrugated shipping case headed for humid conditions will need to be much stronger in order to compensate for this loss. When a corrugated board is produced, the liners and fluted mediums are held together with a starch adhesive, typically food grade corn starch. In its most basic formula, corn starch adhesive has very little moisture resistance, which would cause the composite layers of corrugated board to separate in high humidity conditions. Knowing this, corrugated board manufacturers add small amounts of resins to the adhesive to give it moisture resistance. The result is known as moisture resistant adhesive (MRA). The degree of moisture resistance varies from manufacturer to manufacturer and also depends on the conditions where the boxes will be used.

1255 views0 0

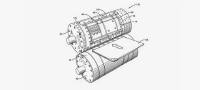

ROTARY CUT OFF KNIFE THE MECHATRONIC SOLUTION For the Corrugated Paper Board Production Line

With the term “mechatronics” we refer to the combination of mechanical engineering, electronic engineering, computer science and automatic control with the purpose of evolving machine manufacturing into the next generation. The rapid growth of electronics has led to the re-designing of traditional mechanical elements. Arrays of gears and mechanical cams, are replaced with “virtual” elements materialized as software in suitable controllers and servomotors drives. New possibilities appear in maintenance, flexibility, extendibility, easy reconfiguration, after sales support, but also possibilities of networking and interconnection with the factory automation. A typical mechatronic configuration is constituted mainly by controllers, drives and servomotors but also various other elements are essential for the concretization of the particular automation task e.g. I/O components, encoders, sensors etc. The heart of the system is the controller. Modern controllers are powerful systems that incorporate different operations in a single unit. Raycon Systems and Machines ltd, in collaboration with Siemens SA, introduced a rotary cutoff for the corrugated paperboard production line based on the mechatronic philosophy. A schematic illustration of such a machine is shown in Figure 1. The rotary knife motion trajectory calculation is a non-trivial task since several position/speed restrictions must be met: ●At the cutting point the rotating blade should have a linear velocity equal to that of the moving carton board (synchronization phase). ●The time it takes for the blade to complete a full rotation must equal the time it takes for the board to traverse the desired cutting length. Thus the rotation time of the blade depends on both the paper speed and the desired cutting length. ●To minimize vibration and ensure minimal mechanical stress, the motion profile of the blade, should be as smooth as possible without violating the previous constraints.In the past, this functionality was achieved solely by mechanical elements, where a change in cutting length translated into a change of the transmission ratio, through mechanical adjustment of pulley belts. Although this was prone to low precision, wear, instability, and the whole system was of increased complexity and high maintenance need, it was the only option for high-speed rotary cutoff knifes in the corrugated paperboard industry for more than 50 years. A reason for this is that, despite its drawbacks, the mechanical cutoff, if high quality constructional standards were met and proper maintenance followed, was able to achieve a good cutting accuracy of (0.5cm). Possible improvements therefore were justified only in the need of higher accuracies, less than (0.5mm). As this need emerged and the trend in the field of electronics and control was reducing the cost of high-speed controllers, affordable servomotors and programming applications to drive them with electronic cams, began to appear. Mainly due to the initial high cost of servomotors, attempts by using DC motors, also appeared at this point but introduced great complexity with an impact on reliability, support and performance of the final system. The current state of the art, in the corrugated paperboard industry, is using servomotors driven by high-speed controllers with customized software to achieve cutting accuracies less than 0.2mm. Usually, the companies that manufacture production machinery develop "close" software that drives the servo rotary cutoff knives. The solution presented here, for the rotary cutoff knife, extends the current state of the art, mainly because it introduces the concept of "open" mechatronic technology in place of "custom" software that usually exists today in these applications. The presented herein rotary cutoff is a product of Raycon Systems and Machines ltd. The mechanical part is based on the design and construction of A. Raftopoulos ABEE. The engineering approach gives emphasis on simplicity and durability; the main drive is conducted with a pulley and timing belt. This ensures accurate transmission, vibration reduction, low mechanical stress, and the possibility of reconfiguration for various specifications. The motion control part of the rotary knife is an implementation of Siemens mechatronic technology.The automation is realized by means of a Simotion D controller that is used for calculating the desired trajectory. The restrictions in position and velocity (synchronization with the paper at the cutting position and rotation time according to the cutting length and paper speed), dictate a specific cam motion profile, which must be recalculated continuously, in real time, so that the restrictions are met, even after dynamic changes in cutting length and/or paper speed. For this reason, the position of the knife is resampled every 125 millionths of a second and the cam profile is recalculated by polynomial interpolation of fifth order (quintic). The motion control signals are transmitted to a Sinamics S120 servo rotation regulator, the logic of which is incorporated in the Simotion controller, driving a 1FT7synchronous servomotor. The actual set points for position/speed are provided by an external measuring encoder. The system is operated through a Simatic touch panel connected via profibus network. Due to the inertia of the rotating load, the motor operates as generator, during braking. The returned energy can be consumed either in braking resistance, or returned in the supply network by means of a suitable Sinamics S120 module. In the later case, a significant reduction in energy consumption is achieved. The rotary knife solution presented herein evolves the current state of the art, mainly due to the mechatronic design, in contrast to the logic of "custom" software. Mechatronic design, in this case, means that all the above theoretical algorithms, preconditions for the proper functioning of the cutoff knife, are implemented with existing building elements that have been developed, optimized and brought to an “embedded” form for general use. The reported solution therefore, is not "custom" software, but instead is an “open” implementation of the mechatronics library design infrastructure available by SIEMENS. This paradigm has important implications, both for the end-user-purchaser of the machine, but also for the cost-effectiveness of the manufacturer. Firstly, avoiding “custom” software solutions contributes to the autonomy of the equipment. With respect to after sales, this is a critical issue for the end-user. At the same time, this autonomy adds value to the rotary knife as a product. This is an issue very important for the manufacturer, as it involves SIEMENS in the after sales global support network with worldwide capabilities. The robust repetitive cutting accuracy, the capability for mark cutting and the “on the fly” change of cutting length, are the features that differentiate this solution from similar "custom" solutions. These were integrated at relatively low cost because RAYCON succeeded in utilizing the existing modular mechatronic infrastructure of SIEMENS rather than developing "closed" software from scratch. As a result, even more innovative features were incorporated, like micro adjustment in the cutting profile for cardboards of variable thickness. All these advantages, in combination with the ease of maintenance, reliability, scalability and the possibility of incorporating a web-in production line automation (totally integrated automation) not only position this rotary cutoff, at the top of the global state of the art in corrugated industry, but also make it a first-choice product, capable of competing at an international level.

1105 views0 0

Corrugated packaging: 5 steps towards the perfect packaging solution for your product

The perfect corrugated packaging protects your product during transport, is optimally stackable on pallets, produced sustainably, and 100% recyclable. Depending on the application, it also supports your brand values. Therefore, numerous criteria must be considered. In this blog post, we will walk you through all the steps you need to start developing the ideal packaging solution.1. Corrugated packaging: where to start? Everything starts with the product that you want to pack:· How much does it weigh including primary packaging? What material is the primary packaging made of? In some cases, your goods can be packed directly in the corrugated box, i.e. the primary packaging coincides with the secondary packaging. · What are the dimensions of the primary packaging? How many primary packages should be packed in the corrugated box?· What constraints need to be considered when stacking pallets of finished products in your warehouse?· What does your downstream supply chain look like: long-distance transport, transport in humid conditions, etc.?Based on your answers, we determine the quality of the packaging you need and choose the perfect configuration. What do you need to know about this? In the corrugated cardboard sector, the following paper types can be distinguished:· The fluting: the inner layer of the cardboard which is used to produce the required flutes. These flutes primarily determine the strength of the box.· The liner: the outer and inner layers of the cardboard which will also determine the box’s appearance. There are various possible grammages and flute types. The grammage expresses the thickness of the cardboard. The higher the grammage, the stronger the cardboard. A paper type with a high grammage will therefore weigh more and in most cases offer better protection, but it will often also carry a higher price tag because of the higher quantity of raw materials.The flute type determines the thickness of the corrugated cardboard. The thinnest cardboard types have a single flute and their name includes one letter. Compound cardboard types have a double flute consisting of two single flutes; in principle, any combination of the following types is possible: · F flute: 0.7 mm· O flute: 1.7 mm· E flute: 1.15 mm· B flute: 2.5 mm· C flute: 3.5 mmNot only the paper type, but also the flute type will therefore determine the characteristics of your packaging. The print quality will also depend on the chosen flute. A box with a finer flute is better printable on the outside.2. The right box for every productCardboard boxes come in all shapes and sizes. One may have four closing flaps to be sealed by taping, another may have a lid and handles, while yet another one may have convenient inserts. Our professionals listen to your needs in order to select the perfect design.Virtually all designs correspond to an international code developed by FEFCO, the European Federation of Corrugated Board Manufacturers. The codes consist of at least four digits and relate to the style or design of the box. Code 0201, for example, stands for the American folding box – also known as regular slotted container (RSC), the most well-known of all cardboard packaging. The basic four-digit code can be extended to accommodate additional details, variations or a combination of styles. The American box code, for example, can be extended to 0201-03, where 03 indicates a different version of the basic box. There is already a wide range of FEFCO standards that are used by cardboard producers throughout Europe. However, FEFCO keeps re-evaluating and supplementing the codes to keep up with the rapidly innovating sector. 3. The best dimensions for cost optimisationThe FEFCO standards define the form of the box, but not its dimensions. This is where our packaging experts step in. Together with you, they will look for the perfect solution for protecting your goods, optimising your packaging process, and making your logistics chain more sustainable.The inside dimensions indicate the volume available for the primary product. Next, we note down length x width x height, expressed in millimetres. The length is always greater than or equal to the width. The outside dimensions indicate the volume available for the packaging on the pallet and possibly also the space taken up by the shelf-ready packaging on the store shelf. Finally, we also determine the flat size, which indicates the amount of corrugated cardboard that is needed to produce the box. The larger the format, the higher the price tag of the packaging. 4. The right technique for your printing needsAfter the previous technical steps, it is now time for the most enjoyable step of all: your personal print! Your logo, slogan, image, or graphic design must make your packaging a visual treat. However, also be sure to consider technical product information, barcodes or QR codes. You should therefore devote sufficient attention to this stage. The print technique depends on the number of colours in your design and the cardboard type. Three common techniques can be distinguished:· Flexo printing supports all colour designs with four different basic colours (CMYK), possibly with two extra pantone colours, and possibly finished with a varnish. The plates are flexible, so that the machine can neatly print on the corrugated surface. It is still the most commonly used and most cost-effective print technique, especially for large print runs.· Digital printing is booming because it is the most flexible option, certainly for print runs below 2000 m2. The inks are more expensive, but the print can easily be customised. Ideal for startup business sectors, smaller runs or seasonal packaging designs.· Offset printing provides excellent print quality. However, the plates used are hard rather than flexible, so it is not suitable for all materials. Our experts will advise you in detail about the options. 5. Optimal palletisation and storage of your order Our sites are equipped with different machines so that the minimum order quantity varies strongly, but on average it is around 2000 m2. For smaller runs, for example, you could contact our display division or one of our specific sheet plants in the Benelux, France and Norway. Our experts will be happy to provide you with further details. How we will palletise and deliver your order depends on your logistic processes. Do you have sufficient space to store the goods or do you opt for storing them at one of our numerous warehouses? Do you prefer to work on a make-to-stock or on a make-to-order basis? Based on your desires, we also determine the pallet type, the stacking method and the type of strapping – possibly in combination with film - to keep everything neatly in place and sealed, where appropriate, as well as top protection of the pallet.

1201 views0 0

Corrugated Post-Print Best Practices

Today, all manufacturing industries face challenges that require changes from past business practices. Twenty, even ten, years ago the consumer was a passive actor who accepted market proposals. Now the end-user is an informed and sophisticated consumer who seeks differentiation, personalization. Today’s consumer has a clear understanding of the supply chain and the value it brings to key aspects of packaging, such as the environment and sustainability. Companies seek greater efficiencies and more productive use of resources. Because of this, Consumer Packaged Goods (CPG) companies must produce better packaging while controlling their manufacturing costs and minimizing time loss and materials.Flexo's EvolutionThe flexographic industry is no stranger to this “new” reality and strives to reduce response times and provide packaging with greater shelf impact at competitive prices. All this PLUS the trend towards shorter runs as CPGs require their brand identity be maintained regardless of the region, the printing method, or the substrate. Successful converters have adapted to this new reality, by increasing production by establishing standard procedures, assuring adequate tools are available and providing constant training to their production staff. This allows successful converters to increase production with minimal cost increases.Why change what has been done for so many years? Because the needs of customers are changing!Evolution of the BoxThe corrugated box has also evolved from a means of product protection in shipping to an important sales tool. Even the simplest, one color box requires adequate legibility with barcodes or QR codes that are fundamental to the organization of inventories, selection, and distribution. With the great e-commerce boom, companies are forced to respond with customized boxes, while continuing to ensure highly efficient operations.Considering the above, we will discuss some practices for the press floor that can be implemented to improve efficiency and reduce errors for the post-print corrugated market.Before going to pressAfter proper plate processing (liquid resin, analog sheet, or digital sheet), it is necessary to inspect for defects and measure the plate with a micrometer to ensure the gauge and relief tolerances are within specification (Image 2). Any low point will cause printing failures and over-printing which affects the printed result AND the strength of the box. Additionally, the more consistent the gauge, the longer the life of the plate on press. The use of a Shore A calibrator will confirm that the hardness of the material is ideal for both the graphics to be printed and the substrate used (Image 3). Corrugated materials require low durometer from 25 to 40 Shore A. All instruments used must be properly maintained and calibrated following the manufacturer’s recommendations to ensure accurate and precise measurements.Image 2. Digital micrometer for reading the thickness of the plates. The plate should be supported on a table perfectly parallel to the floor and with a sufficient area to prevent movement. Source: FLEXOGRAPHY Principles &Practices. 5th Edition.Image 3. The Shore A gauge of durometer measures the penetration of its cone on a soft material. Source: FLEXOGRAPHY Principles & Practices. 5th Edition.Prior to mounting the plate, check the work order to confirm measurements of the box design, number of colors, plates per color, and other specs. Cutting the plates, whether manual or automated, must be precise, clean, and without burrs that impair adhesion to the carrier. Beveling the edges of the plate is highly recommended (Image 4). Beveled edges improve the contact area with the sealant and reduce the risks of the plate lifting during the production run. The polyester backing, as well as, the carrier must be thoroughly cleaned to remove any traces of dirt that may affect the application of the rigid mounting tape. Typically, when there is poor adhesion between these components, there are high areas that print with more pressure on the cardboard. After the placement of each plate on the plate roll, it is important that constant pressure is exerted with a rubber roller to improve adhesion and avoid bubbles. The plate mounting must not only guarantee an exact registration but also an even impression of each color.Image 4. Beveled edges and cut corners of a plate.RegistrationThere are different targets available for manual or automatic evaluation. The designer, mounting operator, and printer must agree with the type and location of the registration marks (Image 5) Everyone involved must understand how to use the marks to clearly communicate if a registration problem arises from design, mounting, or printing. Flexographic Image Reproduction Specifications & Tolerances (FIRST) supports the use of the Railroad Track Target which contains implicit measurements for lateral and circumferential adjustment thus avoiding the use of a measuring tape reducing the time required to achieve aligned images. The goal is to place the colored triangle on the centerline. These targets along with the traditional crosses should be placed in the four corners of the sheet. Image 5. The orientation of the register targets on the sheet. Source: Cordes PorcherOn pressOn press, organization and cleanliness are fundamental and necessary. A lean manufacturing mentality must be maintained following the basic principle of the 5s which focuses on how best to organize the workspace to maximize efficiency: sort, set in order, shine, standardize, and sustain. The tools and supplies should be easy to see, easy to obtain, and easy to return, guaranteeing only the materials needed for the print run will be on the press. PressA program of preventive maintenance should be agreed upon for the press with the personnel dedicated to this task: inking systems prepared and adjusted to provide the thickness of the desired ink film to the plate; rollers under concentricity, conicity and parallelism tolerances confirmed by the manufacturer; bearings and bushings in perfect condition and properly greased; register and material guidance controls; and drying units operating efficiently with the airflow itself. Negligence in maintaining these items and delayed replacement of worn items will result in problems of quality and productivity.AniloxAs for the ink film thickness, it is essential that the pressman knows their anilox. They must know the linescreen and volume, and the condition of the anilox. Although the change of anilox in a corrugated printing machine is relatively infrequent, a routine cleaning program must be carried out. Equipment that incorporates the recommended cleaning chemical is available to complete the cleaning on the machine. Likewise, an inventory audit must be carried out, relying on the manufacturer expertise.InkAnother critical element to control on press is the ink. Those used in the corrugated industry are water-based and require an alkaline pH (pH> 7.0) to keep the resin in solution. This is achieved through the incorporation of chemical substances such as amines that tend to evaporate during the run which reduces the pH and increases the viscosity. This causes variation in the color density, dirty impression as the ink accumulates on the plate due to a poor redisolubility, excessive generation of foam, and accumulation of paper fibers on the surface of the plate. To maintain consistency in the control of the color during printing, both pH and viscosity should be measured frequently and pH corrective solutions should be added to maintain stable ink properties. The addition of water reduces the pH and should be used with great care as the color strength can also be affected. Before making an adjustment in the viscosity, one must ensure that the pH is in the range recommended by the supplier (pH 8.5-9.5) (Image 6). Any measurement carried out must have adequate and regularly calibrated equipment and the ink temperature recorded. Image 6. The pH should be maintained in a range of +/- 0.3 during the print run to ensure a stable behavior of the ink. Source: Flexographic Image Reproduction Specifications & TolerancesOnce the plates are placed in the press, the next step is to confirm adequate inking through the appropriate adjustment of the pressures: anilox-to-plate and plate-to-substrate. First, verify the ink flow to the anilox is at its optimum level, the printing plate must be completely inked without excesses through the slow approach of the anilox. Then move the whole assembly towards the cardboard substrate. Confirm that the substrate has printed the entire plate and stop the adjustment at that moment. The anilox adjustment should be done first and last to avoid excess ink on the plate. The objective is to apply the lowest possible pressure that allows a consistent impression; excessive pressure will cause greater dot gain, premature wear of the plate, and considerable crushing of the board. Drag Targets can be useful to visually evaluate excess pressure depending on the pattern shown in each one (Image 7). If a more objective evaluation is desired, the inclusion of control strips with different dot percentages will allow the reading of the dot gain experienced by each: a minimum point patch, quarter-tone, halftone, shadows, and solid block would be a good sample for process control. Regardless of the target used, they must be placed on both sides of the press to ensure the parallelism of the rolls. The values must be correlated with those established during the press fingerprint test to confirm if a certain value read with the densitometer confirms or rules out an over impression.Image 7. Impression targets: circular (anilox/plate) and hexagonal (plate/substrate). Source: Flexographic Image Reproduction Specifications & Tolerances.Plate CleaningDuring the press run and at the end of the run, cleaning processes must be carried out on the plates which can extend their useful life. Immediately after the production ends, clean the plates to prevent the ink from drying completely. A brush with soft and fine bristles (nylon or natural fiber) or a suitable sponge must be used for this operation; never use brushes with metal bristles or rough cloths. Moisten the plate with a cleaning solution prior to brushing it; a solution of lukewarm water with an alkaline pH (> 9.0) works well to remove the ink from the surface. When in doubt contact the supplier to develop a swell test under the established protocols and determine the variation of caliber and hardness using a small sample of the plate. It is not necessary to aggressively brush the plate as excess pressure can damage the surface. During brushing, apply generous amounts of the cleaning solution to keep the surface moist and avoid scratching. Improperly cleaned plates can stick together, develop surface cracks, and become more difficult to clean for reuse. After cleaning, dry the plate with an absorbent soft paper or forced air to remove residual water.Plate StorageFinally, store the plates vertically. The storage area should not exceed 100°F (38°C) and should be located away from ozone generating sources such as motors that generate electrical discharges and energy sources. Keep the plates in an environment free of dust, keep them dry, and at room temperature. Protect plates from exposure to direct light sources that can cause softening, brittleness, and discoloration.Image 8. The protection of the plates to UV light will prolong their useful life. Avoid direct exposure using filters.ConclusionUndoubtedly, there are more areas that can be considered but the most important thing is to understand the variables, control them, and rely on suppliers to define standard operating parameters in each of their areas of responsibility. Knowing the capabilities of the printing system is critical through press fingerprint tests to make consistent designs. However, the capacities of the personnel of each area and the processes that are carried out day after day must also be reviewed. The best printing equipment may not provide the expected results if employees are neither properly trained nor empowered to implement procedures to make their work more efficient. The objective is not to work harder but to work smarter, and this is where the company that adapts best manufacturing practices will maintain a differentiated position in the market.

1058 views0 0

Preventive maintenance of corrugated cardboard production line

Carton enterprises pay great attention to the prevention of corrugated board production line equipment and maintenance. Corrugated board production line of preventive maintenance of the goal is to prevent equipment failure. Preventive maintenance can protect and enhance equipment reliability by replacing worn parts prior to failure of parts and equipment. Preventive maintenance activities include equipment inspection, whole or local inspection, replacement of oil, lubrication, etc.. In addition, workers can record equipment wear, in order to cause parts of the system before the problem, clear need to replace, repair and wear parts. Recently, advances in testing and diagnostic tool technology have helped carton companies maintain equipment accurately and efficiently. Value of preventive maintenance Preventive maintenance said there are a lot of misunderstanding. One is that the high cost of preventive maintenance. According to this logic, preventive maintenance than regular shutdown and maintenance costs even higher, that is, the cost of maintenance than the equipment after the failure to be high. In some parts, indeed. However, it is necessary to compare not only the cost but also the long-term profit and cost savings due to preventive maintenance. For example, if there is no preventive maintenance, losses resulting from unplanned downtime can occur. In addition, preventive maintenance will be due to the improvement of production efficiency and equipment during the use of cost savings. Preventive maintenance to bring long-term benefitsImprove the reliability of the system;Reduce the cost of the replacement part loss;Reduce system downtime;Spare parts inventory management; From long-term impact and cost comparison, preventive maintenance is more meaningful than routine maintenance when equipment failure occurs. When to carry out preventive maintenance? Only when meet the following two conditions, to carry out preventive maintenance is meaningful:A: fault problem element rate. In other words, the failure rate of the component is increased, which means wear and tear. However, preventive maintenance is meaningless if the failure rate of an element is too high (reflected by exponential distribution). Two conditions: the total cost of preventive maintenance activities should be lower than the total cost of maintenance and maintenance. Pay attention to maintenance maintenance costs, including visible and invisible costs, such as downtime loss, production time loss, lost credibility, etc.. If meet two conditions, preventive maintenance is meaningful. In addition, according to the cost ratio, the best time for preventive maintenance of individual parts can be calculated by computer. Preventive maintenance requirements should focus on each machine each parts, maintenance according to plan. Usually, refer to the machine manufacturer to provide a list of specific maintenance tasks and common fault problems. Each maintenance supervisor shall organize these tasks in the framework consistent with the plant procedures and plans. Sometimes, maintenance supervisors may be different from machine manufacturers in judging tasks and plans. The maintenance of equipment failure, relies heavily on the maintenance personnel supervision skills. Therefore, must establish the document database for all these processes. That is, to create a computer program to store all this information and guide the maintenance of the machine. To some extent, preventive maintenance work professional requirements, the need for trained technicians to competent. Electronic control work especially to technicians to complete. The maintenance supervisor responsibility is not small, to carry out training and appropriate task assignment of machine maintenance personnel.Corrugated carton production equipment industry and other industries as equipment is so complex and difficult to serve". A typical maintenance of good processing equipment, in principle, as long as the use of high-quality raw materials: corrugated cardboard, printing plate, die cutting mold and ink will be able to process high quality carton products day and night. When the factory production deviates from the normal operation plan, the use of old equipment, damaged plate and mold, of course, will lead to product quality problems. Worn bearings, gears, rollers and other machinery is the root cause of the landslide mass.

1053 views0 0

Ten solutions of waterproof and moistureproof for corrugated box

Corrugated boxes have been criticized by the market for their poor water and moisture resistance. Especially in recent years, the market scale of cold chain packaging such as fresh ice meat, fruits and vegetables, medicine and so on has become larger and larger. The corrugated packaging industry urgently needs to fundamentally solve the problem that the box packaging is easy to collapse after being damped.01. Heavy sizing box boardIn the paper-making process of box board paper, the surface of the box board paper is heavily sized to ensure that the water drop is not penetrated within 5 minutes. Usually a large number of water-resistant additives are added to starch paste, such as urea formaldehyde resin, melamine formaldehyde resin, polyvinyl butyral, etc. But the cost of the water-resistant agent is high, and it is easy to cause problems such as uncoating in the production process of corrugated board.02. Coated paperCoated paper is a kind of composite material that coated plastic particles on the surface of paper by tape casting machine. Its main characteristics are oil proof, water-proof (relative) and heat sealing. However, due to the high cost, it is not conducive to widespread use in the packaging industry. 03. Drain corrugated boardIt refers to the process of coating low surface energy substances such as polylactic acid (PLA), polyolefin, polycarbonate, polyamide, polyester, molten paraffin on the surface of paperboard to change the surface roughness and surface morphology of the material. When the hydrophobic corrugated board is subjected to water drenching, a state of water drop on the lotus leaf is formed, and the water becomes water drop to slide down, without seeping into the inside of the board. The cost is very low, suitable for packing dry powder goods, especially the powder which is easy to agglomerate after absorbing water. It is also suitable for packing the goods that often go in and out of the cold storage. It is easy to condense on the box wall after being taken out of the cold storage. After hydrophobic processing, the paper board will not significantly reduce the compressive strength before the dew evaporation, which can effectively protect the goods.04. Waterproof corrugated boardAlso known as waterproof or water retaining corrugated board, its surface is almost impervious to water for a long time, but it cannot be immersed in water, otherwise it will lose its waterproof performance. Water blocking corrugated board is often used curtain coating method. The melted synthetic resin or paraffin mixture is coated on the surface of corrugated board to form a layer of resin film or wax film. If necessary, double-sided coating can also be carried out. Water blocking corrugated board is mainly used for packaging salted products, frozen food and fruits and vegetables. Because of the soft paraffin layer on the surface of corrugated board, it is also suitable for packaging high finish furniture, piano, safe and precision machinery, which are easy to scratch.www.chinacartonmachine.com05. Water resistant corrugated boardWater resistant corrugated board is a kind of paper whose strength is not obviously reduced after long-term immersion in water. There are two kinds of equipment and technology for producing water-resistant corrugated board. Its processing principle is similar to that of impregnation. Water resistant corrugated board can be measured by instrument. The so-called water resistance is that the corrugated board is immersed in water (20 ± 2 ℃ tap water) for 30mm, soaked for 1h, and then tested for its breaking resistance and edge pressure strength. The residual strength is required to be no less than 75% of the standard strength (before immersion).Water resistant corrugated boxes are used to carry live fish, seafood and a class of commodities with high water content. However, the recycling of such cartons is difficult, and the EU has restricted their use.06. Surface polish corrugated boxPolishing is a common process for post press processing of packaging products. After the product surface is polished and coated, it can enhance the water resistance, sun resistance, friction resistance and pollution resistance of the printed products. At the same time, it can also improve the surface brightness of the products and greatly improve the quality of the products.The polishing process of the corrugated box is usually that the surface paper is pre printed and polished, and then mounted into the corrugated board, and then die-cut into the carton. It can also polish the surface of corrugated board directly, but the waterproof effect is not good, and it may damage the compression resistance of the carton.07. Surface coated corrugated boxLaminating is the process of covering plastic film such as polypropylene on the surface of printed matter, and using adhesive to make it stick together after heating and pressure. Lamination technology is divided into pre coating and instant coating. After the color box is covered with film, the surface is bright, resistant to friction, with certain waterproof effect, and the folding box is not easy to crack. However, it is difficult to recycle and use the products, and the United States, Europe and other countries have restricted their use.08. Aluminum coated kraft boardToyo Steel Co., Ltd. has developed a 0.02mm ~ 0.05mm thick pure iron foil, which is treated by galvanizing, nickel or tin antirust, and extruded together with kraft paper and polyethylene film to make composite paperboard. It is used for making cartons, not only waterproof and moisture-proof, but also shielding electromagnetic wave and static electricity. It is especially suitable for packaging of aquatic products, fruits and vegetables, electronic instruments, semiconductor devices and electromechanical products 。 After compounding the aluminized PVC film and kraft paper, the cartons are made, which also have the functions of waterproof and moisture-proof.09. Corrugated paste added with water-resistant agent cartonIn the production process of corrugated board, a proper amount of high molecular polymer (also known as crosslinking agent or bridging agent) is added into the starch adhesive, which will replace the hydroxyl group in the starch molecule, making the corrugated paste line have better waterproof and moisture-proof effect. When the carton enters the cold storage or humid environment, it can prevent the collapse of the carton due to the moisture absorption and emulsification of the corrugated paste line.As for the often publicized products that can improve the bonding effect of cardboard and enhance the stability of bonding, there are some exaggerations.10. Carton vent is moisture-proofFor the products with heat degree in the packaging of beer, a certain amount of hot steam formed in the box may be absorbed by the box, and then the compressive strength will decrease. In view of these situations, the common practice is to punch two 18 mm diameter air holes respectively on the proper position of the side mark of the carton.

1088 views0 0

Nancy Liang

Sales Manager

Industry experience:20 Year

language:Chinese,English

Responsible area:

Contact