What Kinds of Conveyor System in Corrugated Factory?

What Kinds of Conveyor System in Corrugated Factory?

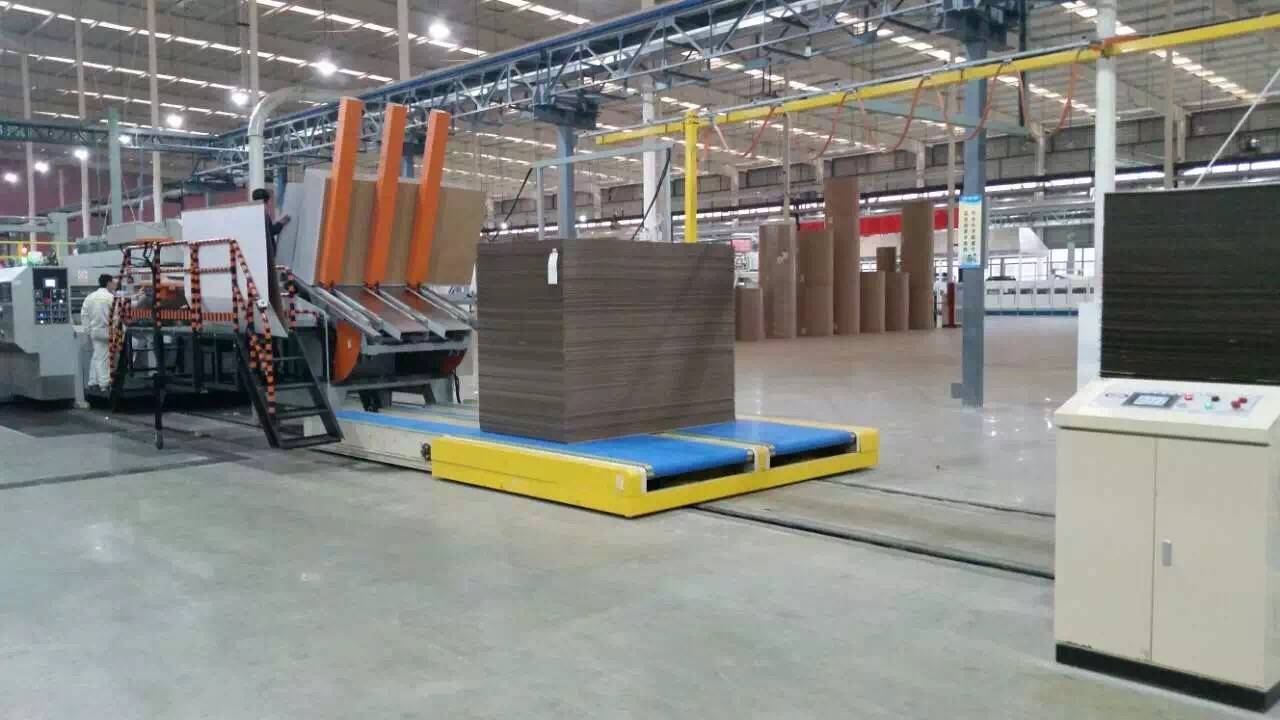

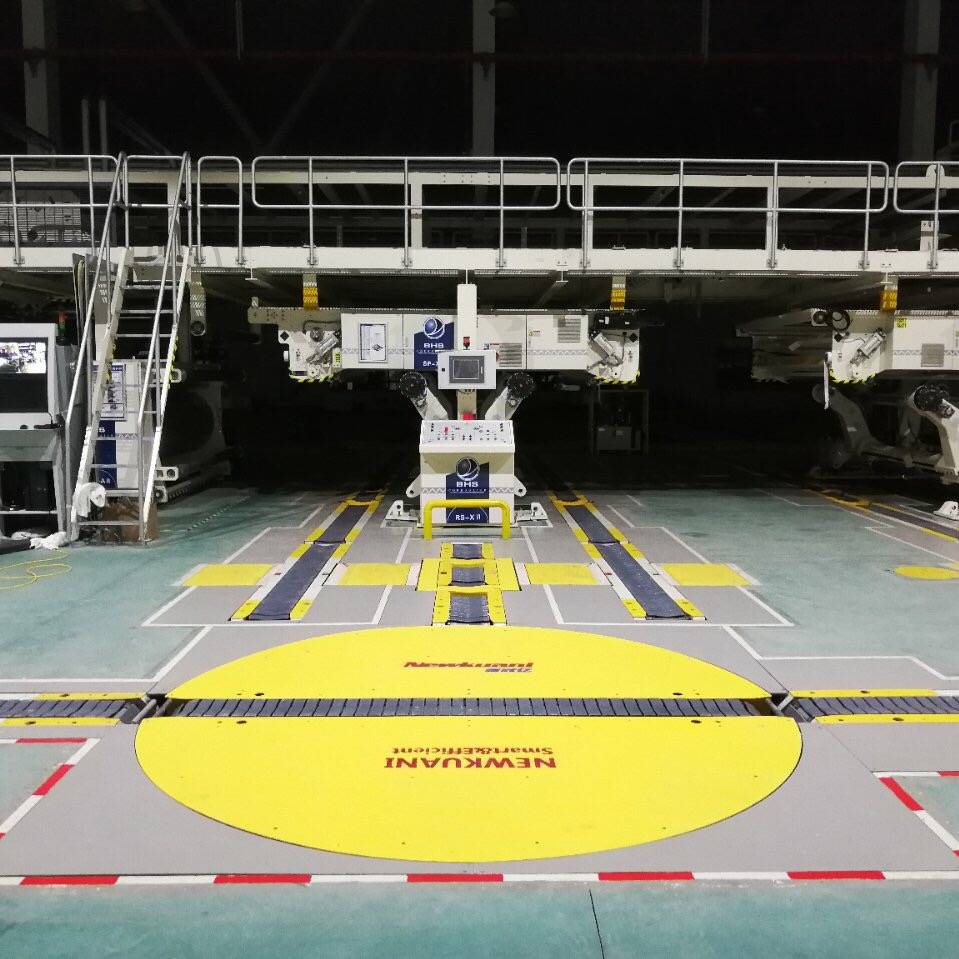

The rise and improvement of the automatic conveyor system of the carton factory, known as the "third source of profit"in the United States, Japan and some European enterprises,with the development of automation equipment, the improvement of the conveyor system may be related to the enterprise management revolution, but also greatly affect the production efficiency of the enterprise.In China, many carton factories are still using the original drum conveyor, some larger carton factories are equipped with semi-automatic conveyor, but automatic conveyor system configuration in the carton factory now is not widely equipped.However, with the continuous promotion of intelligent manufacturing in carton industry, automatic conveyor system will become the standard configuration of most carton factories in the future.Definition and Performance of Automatic Conveyor SystemIn the carton production process, have you ever encountered these problems: workshop cardboard transport and storage management take time and effort? Drum conveyor being installed yet play the efficiency of the conveyor system?Often scratch corrugated board in the conveying process?Shipment, waybill, tallying cause burden of management personnel? Poor conveyor system efficiency and design, manual work conveyor can not keep up with the speed of corrugator production line?When the automatic intelligent conveyor system with high intelligent degree appears,the conveyor problems that plague carton factories are slowly disappearing. On-line production is the basis of intelligent manufacturing of carton factory, and the automatic conveyor system is the "expressway" for the carton factory to realize the real on-line production. Automatic conveyor system can help the carton factory to improve production efficiency, reduce loss, reduce the number of workers. It can be said that the automatic conveyor system makes the carton production catch the quick-pace development on the intelligent manufacturing.To put it simply, the automatic conveyor system needs intelligent conveyor, ground roller/crawler conveyor, 90-degree / 180-degree rotary table, x-y lateral load shifting, corrugator automatic separate system, automatic up/down pallet, and through the computer system to make these supporting intelligent connected. After the system is set up, the staff only need to input the instruction on the computer, the automatic intelligent conveyor system can complete the conveying task quickly and accurately.The performance characteristics of automatic intelligent conveyor system are as follows:1. Automatic transfer cardboard from corrugator stacking exit to post-processing equipment such as printing machine, laminating machine, glazing machine and foot press;2. Effectively improve the management and transportation efficiency of the warehouse system;3. Real-time and visual workshop management to make the warehouse situation clear.4. Production records and performance statistics can be made for each machine for managers' reference. Integral Part of a Fully Automated Conveyor SystemFrom the perspective of carton production process, automatic conveyor system includes the following three stages, namely, base paper conveyor, semi-finished product conveyor and finished product conveyor.1. Base Paper ConveyorThe conveyor of base paper is mainly responsible for the transport of base paper. By building an intelligent ERP system of raw paper warehouse and combining the application of bar code and chip, the enterprise canthe dynamic quantity and location information of each roll of raw paper in real time.The use of raw paper conveyor will be conducive to raw paper procurement management, butt roll online management, performance assesent and cost accounting.The base paper conveyor system is easy to operate and can realize the automatic transportation, paper loading and paper returning of the base paper.At present, there are 3 modes of base paper conveyor:No.1: Single Track in and out Mode That is, a paper cylinder with a track.Each track is both in and out of the paper, this mode of investment is the minimal, but is not suitable for high-speed machine production operations.Because the original paper in and out are costing time, only have to send in after waiting for the inside of the original paper out , which does not meet the needs of modern high-speed production.As a result, this pattern is relatively rare.No.2: Four Tracks that Only Go in and Plus one Vertical Track That is, these four tracks only going in, the base paper from the other end of the longitudinal rail going out, the base paper directly being transported to the base paper warehouse from the other end after a long longitudinal rail .This model is fast, but at the same time because it takes up a lot of space, so the investment is also large.Therefore, though the layout is the most reasonable, but the investment is large.No.3: Four- in and One-outFour tracks only responsible for the original paper going in , and another track is responsible for the original paper going out.This is to add a track rather than the use of longitudinal track mode, the additional track specifically to let the base paper out, the base paper generally will not come out together, so this mode is relatively better, and less investment and fast-speed.So this is a relatively economical and efficient model at present.After the carton factory is equipped with the raw paper conveyor, the original cost of carrying cars and the labor cost of carrying drivers will be saved.Cost Save:If the cart-holding consumption and the wage cost of the cart-holding driver add up to 70 $ /day, every time the carton factory reduces a trolley, the cost will be reduced by 2,100$ per month and 25,200 $ in a year.2. Semi-finished Product ConveyorThrough ERP intelligent conveyor, semi-finished products will be delivered to the designated place at a specified time, and the conveyor system will be connected to the machine, so that the equipment can realize uninterrupted production.Specifically, to make cardboard produced by corrugated line to the carton production workshop. 3. Finished Product ConveyorIntelligent conveyor of cardboard finished products through ERP intelligent conveyor and vehicle conveyor management, the cardboard finished products are automatically packaged or sealed with winding film and sent to the designated place for loading and delivery.The finished product includes two kinds, one kind of finished cardboard;Another is finished cartons through the printing process .Part of the finished products will be automatically sent to the finished products warehouse through the intelligent conveyor of finished products. Through the intelligent warehouse management system, the dynamic quantity and location of each pile of cartons can be mastered at any time. The other part of finished products will be transported directly from the production workshop through finished products conveyor and loaded into towing boxes.Staff only need to issue instructions through the system, and the finished product conveyor system can deliver the specified finished products to the specified location.